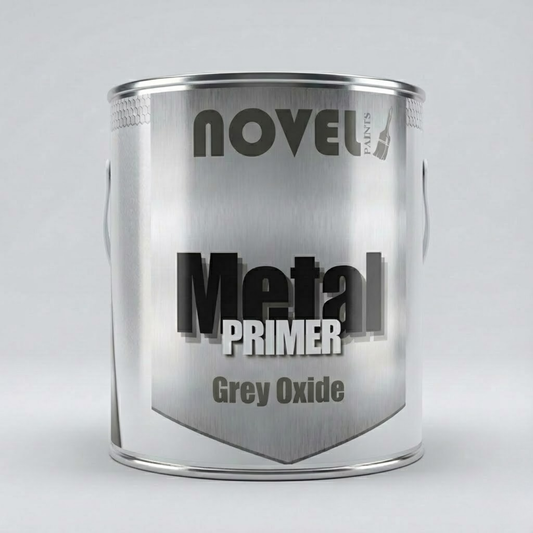

Collection: Metal Primers & Wall Sealers

Prepare your surfaces the right way with Novel Paints Metal Primers & Wall Sealers, a full range of strong, reliable products designed to fight rust, strengthen surfaces, and boost paint durability.

Whether you’re working with steel, gates, grills, machinery, fabrication work, or wall plaster, this collection gives you the perfect base for long-lasting results.

What’s Inside This Collection

• Grey Oxide Primer – Strong anti-rust base coat for steel & metalwork

• Red Oxide Primer – Classic rust-proof primer for gates, grills & machinery

• Red Oxide Zinc Chromate Primer – Heavy-duty corrosion protection for industrial metal

• Clear Seal (Wall Sealer) – Water-based plaster sealer that strengthens walls & stops dusting

Perfect for contractors, welders, painters, DIY users, and property owners who want a clean, strong, durable surface before applying topcoat paint.

Better adhesion. Longer-lasting paint. Stronger protection.

Start your paint job right with Novel Paints.

-

Clear Seal

Regular price From KSh545.00Regular price -

Grey Oxide Metal Primer

Regular price From KSh575.00Regular price -

Metal Primer- Red Oxide

Regular price From KSh1,385.00Regular price -

Zinc Chromate Primer Red Oxide – Anti-Rust Metal Primer for Steel & Iron

Regular price From KSh685.00Regular price

Collections

-

Gloss, Semi-Gloss & Matt Finishes

Discover our premium high-gloss and enamel coatings—engineered for brilliant shine, long-lasting durability,...

-

Special Coatings

Black Bituminous paint Product description It is a hard glossy bitumen based...

-

Undercoats

Get the perfect base for a smooth, flawless paint job with Novel...

-

Emulsion - Water Based Products

Get flawless, long-lasting walls with our high-performance water-based emulsions. From smooth matt...

-

Metal Primers & Wall Sealers

Prepare your surfaces the right way with Novel Paints Metal Primers &...